Key Takeaways

- Foam pigs are essential for maintaining pipeline cleanliness and integrity.

- They can navigate complex pipeline geometries, including bends and varying diameters.

- Advancements in foam pig technology have enhanced their effectiveness in debris removal and inspection.

- Proper selection and deployment of foam pigs can lead to significant cost savings and operational efficiency.

As modern pipeline networks become increasingly complex, the need for efficient and versatile cleaning and maintenance tools has never been greater. One standout solution in this area is the use of foam pigs for efficient pipeline cleaning operations, which has transformed how operators approach both routine maintenance and specialized tasks. These flexible, cost-effective devices adapt to a pipeline’s unique conditions, maximizing flow efficiency and reducing the risk of costly mechanical failures.

From dependable cleaning to intricate inspection and dewatering activities, foam pigs have proven critical across the pipeline industry. Their ability to navigate challenging geometries and provide reliable separation for multiple transported products makes them a fundamental resource for maintaining pipeline integrity, ensuring operational uptime, and driving down ongoing costs.

Equipped with advanced smart technology and evolving to address a wide range of operational challenges, foam pigs offer operators practical, actionable solutions that keep pace with modern demands. Their disposable, maintenance-free nature streamlines pipeline processes, saving companies worldwide time and money.

In addition, the development and adoption of enhanced foam pig technology has opened new doors for real-time inspection, data collection, and process optimization, reinforcing their pivotal role in supporting energy, water, and petrochemical infrastructure worldwide.

Understanding Foam Pigs

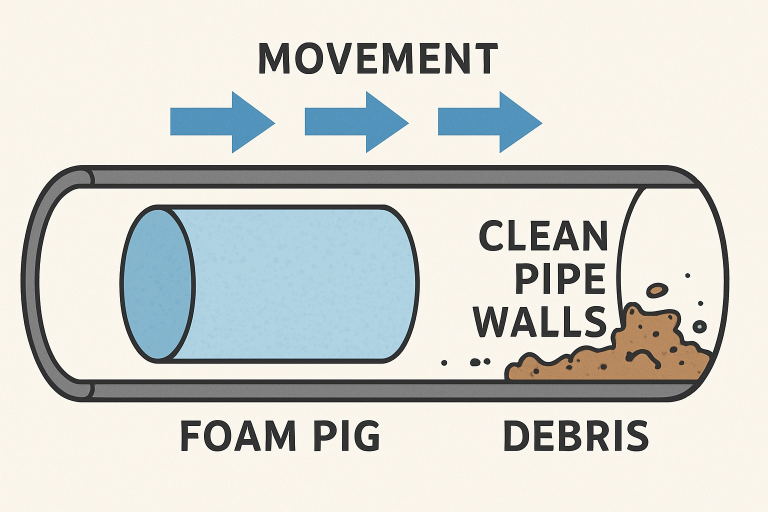

Foam pigs are cylindrical maintenance tools constructed from open-cell polyurethane foam. Their primary design attribute is flexibility—allowing them to conform to the interior shape and size variations of pipelines. Thanks to their lightweight composition, foam pigs easily traverse complex routes, adapting to bends, diameter changes, and other potential obstacles. These features have made foam pigs suitable for a wide range of pipeline tasks, including cleaning, evaluation, and separation. The structure of foam pigs also permits customization. Abrasive coatings, specific densities, and specialized shapes can be tailored for particular pipelines or applications. This ensures each foam pig delivers maximum value for unique operational requirements and environmental conditions.

Cleaning and Debris Removal

One of the principal uses of foam pigs is for thorough, effective debris removal. Deposits such as wax, sludge, and scale commonly accumulate on pipeline walls, hindering fluid flow and promoting corrosion. A foam pig scrapes and absorbs these materials, restoring operational efficiency and mitigating unscheduled downtime.

By traveling with the fluid flow, foam pigs ensure no area of the interior pipe is neglected.

Inspection and Detection

Foam pigs are cylindrical maintenance tools constructed from open-cell polyurethane foam. Their primary design attribute is flexibility, allowing them to conform to the interior shape and size variations of pipelines. Thanks to their lightweight composition, foam pigs easily traverse complex routes, adapting to bends, diameter changes, and other potential obstacles. These features make foam pigs suitable for a wide range of pipeline tasks, including cleaning, evaluation, and separation. In pipeline operations, these devices are inserted into a launcher and propelled through the pipeline by gas pressure, eventually being collected in a receiver, as described by the U.S. Environmental Protection Agency. Proper handling of launchers and receivers is critical to minimizing methane and other volatile compound emissions during insertion and removal.

The structure of foam pigs also permits customization. Abrasive coatings, specific densities, and specialized shapes can be tailored for particular pipelines or applications. This ensures each foam pig delivers maximum value for unique operational requirements and environmental conditions.

Dewatering and Drying

After hydrostatic testing or significant repairs, ensuring that pipelines are completely dry is essential to long-term integrity. Foam pigs, recognized for their high absorbency, are crucial in the dewatering phase of pipeline preparation. By systematically traversing the pipeline, they effectively absorb and expel any lingering water, leaving the pipeline dry and ready for service. Their use in these scenarios directly reduces the risk of internal corrosion caused by moisture residue.

Product Separation

Many pipelines are multi-purpose—transporting differing products in consecutive batches. In these systems, foam pigs serve as physical barriers, efficiently separating liquids or gases and preventing mixing. This ensures product quality is maintained and cross-contamination is avoided, particularly in the oil, gas, and petrochemical industries.

Navigating Complex Pipeline Geometries

Unlike more rigid pigging devices, foam pigs excel at traversing pipelines with challenging geometries. Their compressible structure allows them to navigate extreme bends, tees, valves, and sudden diameter changes—features that are frequently insurmountable to traditional pigs. This capability makes foam pigs indispensable, even in pipeline systems not initially designed for pigging, significantly broadening their application across both legacy and modern pipelines.

Cost-Effectiveness and Disposability

Foam pigs are predominantly disposable, eliminating the need for costly retrieval and refurbishment. This makes them a uniquely cost-effective solution for regular cleaning, swabbing, and product separation. Their affordable price point, combined with the simplicity of use and absence of ongoing maintenance, lets operators maintain pipelines without complex logistical considerations or the burden of inventory upkeep.

Advancements in Foam Pig Technology

The industry shift toward more innovative infrastructure has led to new breeds of foam pigs equipped with sensors that deliver real-time insights. These IoT-enabled devices transmit key operational data, including internal pressure, temperature, and detailed inspection results, empowering operators to make better, data-driven decisions. Ongoing research and development continue to improve the durability, efficiency, and range of tasks that foam pigs can undertake—driving the future of safe and sustainable pipeline maintenance.

Conclusion

Foam pigs have evolved from simple cleaning aids to multifunctional devices that underpin pipeline reliability and efficiency. By offering operators practical solutions for cleaning, inspection, separation, and more, while adapting to the complexities of modern pipeline infrastructure, foam pigs ensure ongoing operational resilience. Embracing advancements in foam pig technology is essential for companies aiming to maintain top-tier pipeline integrity and long-term cost control in today’s increasingly demanding energy landscape.

also read: How to Make a Fizzy Fruit Punch Bar for Weddings and Baby Showers